Parts for the Pioneer 60 Chainsaw Engine can be found here at www.rottmansales.com

The following was written by Bob Chapman (Chappy), on www.rcgroups.com

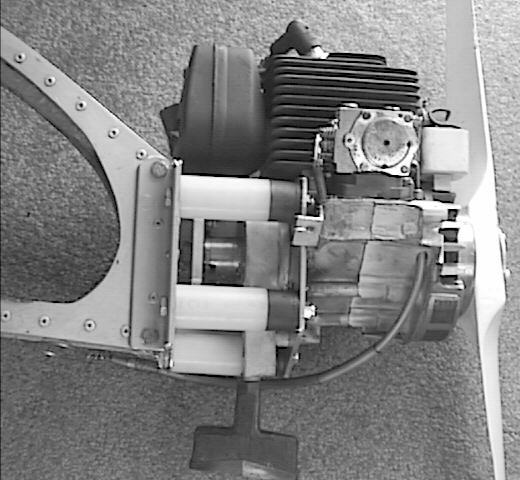

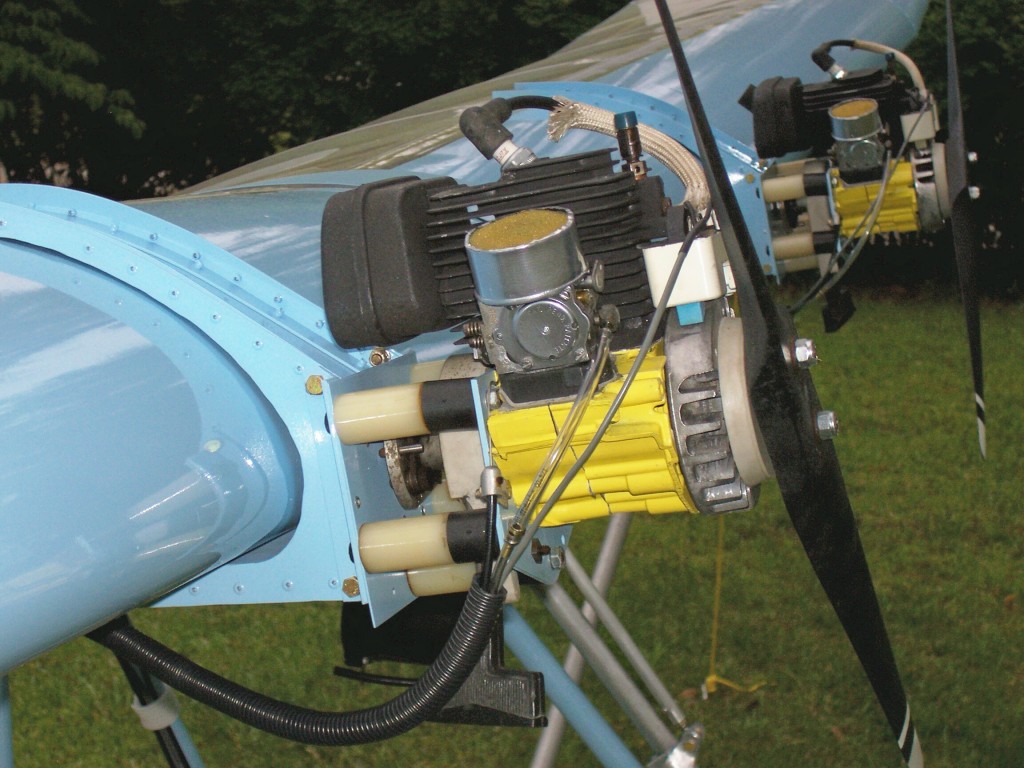

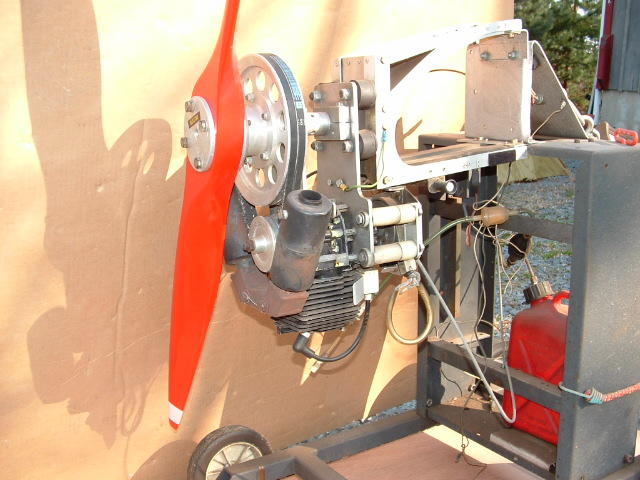

The original Series one Lazair kit came with a pair of modified chainsaw engines. The engines were bandsawed off of the industrial saws at which point they weighed 5 and a half pounds each, or roughly the same as the Joby motors, but making less than half their power. The flywheels were modified so props could be fitted to them, and new housings made by him were used to fit the recoil starters onto the output shafts of the engines. Wooden props were used but before long fiber-reinforce nylon props replaced them. They were made in-house at Dale’s Dad’s plastic injection company, as were the wheels and various other small parts. IIRC, that set-up with the more efficient plastic props made something like 37 pounds static thrust per engine. The engines were somewhat prop-limited so only made about 4.5 HP (each). Re-drives were the big deal of the day so I decided to try my hand at it. One reason was that a friend had covert access to the propeller design program that Paul MacCready developed for the Gossamer Condor project! That enabled me to design (on an Apple IIE clone with 64 K Ram!) a very efficient wood prop. With tuned straight pipe exhausts fitted, I was able to wind the little engines up to rated output (5.5 HP) and I recorded 65 pounds static thrust each thanks in part to the much longer, slower turning props used. My first short flight resulted in severe ringing in my ears for a couple days so a pair of lawn mower mufflers were fitted to each engine. That, and a bit more realistic carb tuning (richer to help lowered astronomical cylinder head temps), dropped static thrust by about 10 pounds each. I think the most fun is taking the plane to fly-ins and when asked about the engines, I respond that they make 11 HP – COMBINED – and watch their reaction. Wish I had videos of some of them! I don’t want to totally hijack this treat from the RC guys so if you’re interested….”